Transforming

Whiterock Quarry

1960

Quarry established

2022

Protranz purchase quarry

2024

Resource consent application and decision

2025

Independent Commissioners appointed by the resource consent authorities issue their decision

2027 (if consented)

Riparian enhancement, managed fill activity commences

2035 (if consented)

Quarrying activities discontinued as managed fill floor and sides are complete

2046 (if consented)

Planting of final vegetation cover

1960

Quarry established

2022

Protranz purchase quarry

2024

Resource consent application and decision

2025

Independent Commissioners appointed by the resource consent authorities issue their decision

2027 (if consented)

Riparian enhancement, managed fill activity commences

2035 (if consented)

Quarrying activities discontinued as managed fill floor and sides are complete

2046 (if consented)

Planting of final vegetation cover commences

For more than 60 years, Whiterock Quarry has supplied lime to the construction and agricultural industries.

In 2022, Protranz purchased the quarry with the vision to fill it with soils and inert construction rubble removed from building and land development sites in and around Christchurch and other parts of North Canterbury. The soil, which has been impacted by historical land use, is currently being sent to Kate Valley Landfill. Once filled, the quarry will be covered with clean soil, shaped to fit with the surrounding hillsides.

Protranz’s long-term intention is to improve riparian vegetation and for the site to be completely covered in grass and native vegetation – creating a space the public can enjoy for years to come.

In 2024, Protranz submitted a proposal to start this work and convert Whiterock Quarry into a class 3 managed fill. The proposal is subject to resource consents which will need to be approved by Environment Canterbury and the Waimakariri District Council.

Class 3

Managed Fill

What is a Class 3 Managed Fill?

In New Zealand, there are five different classes of fills that help ensure the right waste goes to the right place:

Municipal disposal facility (class 1)

A facility, including a landfill, that accepts for disposal waste that is or includes household, commercial, industrial or institutional waste,

green waste, or waste that is not accepted at other classes of facilities.

Construction and demolition fill

disposal facility (class 2)

A facility, including a landfill, that accepts waste that is or includes solid waste from construction and demolition activity.

Whiterock’s application is for a class 3.

Managed or controlled fill disposal facility (class 3 or 4)

A facility that accepts any one or more of the following for disposal:

- inert waste material from construction and demolition activities

- natural soils above background levels from earthworks or site remediation.

Cleanfill facility (class 5)

A facility that accepts only virgin excavated natural material such as clay, soil, or rock, for disposal.

Protranz is proposing a class 3 managed fill for soils that have been impacted by historical land use and inert and sorted construction rubble.

Currently all soil impacted by historical land use in and around North Canterbury and Christchurch is sent to Kate Valley Landfill. Kate Valley is a class 1 landfill that would have a longer life span, and increased methane capture for power generation, if the soils and other inert waste materials that do not generate methane currently being sent there could be sent to a class 3 managed fill.

Protecting our environment

A kaitiaki of the environment

As part of Protranz’s investigations, the company engaged design and environmental consulting company WSP to undertake technical assessments looking at the impact of the proposed managed fill on aspects like groundwater, ecology and air quality.

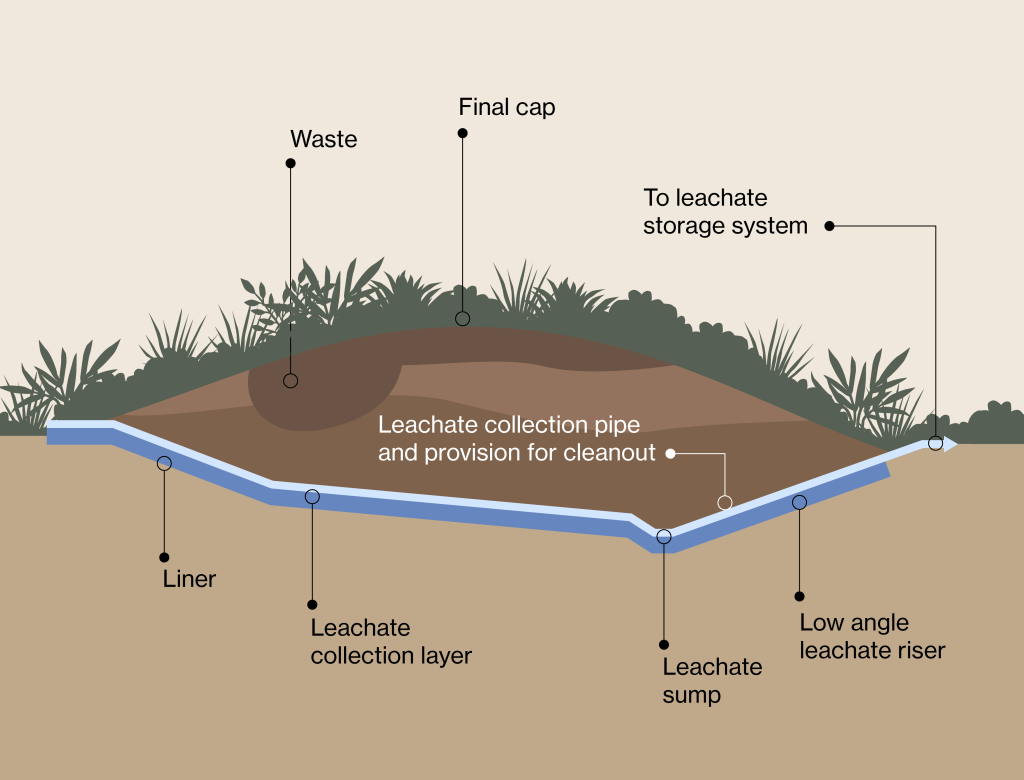

The reports show an incredibly low risk of environmental harm – risks that can be mitigated through the proposed design to apply a liner to the sides and base of the fill to prevent any material from entering underlying rock and minimise contaminants entering groundwater to negligible levels.

The proposed liner is designed and used for a higher-risk class 1 landfill, which gives the highest possible protection to surrounding water and soil. This is not a requirement for a class 3 managed fill, however it’s an additional measure Protranz want to take.

To improve the health of the Karetu River Protranz intends to build a bridge for vehicles to cross the river, install a stormwater management system and sediment and erosion controls, build stock proof fences and undertake riparian planting.

Enhancing the natural area

Once the quarry is filled, in around 20 years Protranz would complete the final capping which would include covering it with clean soil and planting grass or indigenous vegetation to match the surrounding areas.

The final filled area will be covered with a low permeability engineered cap mainly consisting of the overburden material or clean soil, which will be shaped to fit with the surrounding hillsides.

Vegetation is proposed to be tussocks or pastureland for grazing consistent with the adjoining land use.

Overall positive visual and ecological effects are envisaged through:

- Enhancement of identified riparian areas with appropriate indigenous planting.

- Removal of base quarry buildings and tracks.

- Rehabilitation including contouring to match surrounding farmland and revegetation.

- The retention, protection, and enhancement of the adjacent significant natural areas.

- Improved aquatic, bird and lizard habitats.

Several aftercare measures will be undertaken to monitor and record changes in the environment post the closure of the site. The aftercare will continue for at least 10 years once the site is closed, with longer term environmental monitoring required past this period.

Low-emission fleet

Protranz plans to use low-emission trucks to transport lime, soils and construction and demolition materials to and from the site. These trips will be timed around schooling so there will be no movements during school pick-up and drop-off times.

All managed fill material to the site will be transported in covered or sealed transport containers.

Currently, there are around 30 to 45 quarry-related vehicle movements per day. If the managed fill is approved it is estimated there will be 24 heavy vehicle movements on average every day, which will also include service trucks for leachate removal, maintenance and landfill construction.

About us

Whiterock quarry is managed by Protranz, a Christchurch-based company that operates across New Zealand.

Protranz undertake both small and large-scale earthmoving and provide transport services for a wide range of goods, equipment, products, and demolition materials.